Choosing the correct ptc temperature sensor is more important than ever in today's world of electric vehicles and heavy-duty industrial systems. We at Focusens design and make PTC thermistor solutions that keep motors safe, prevent current surges, and make sure they work safely in all situations.

What is the purpose PTC temperature sensor?

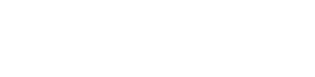

A PTC thermistor is a type of resistor that gets harder to pass electricity through as the temperature rises. A PTC sensor is different from most sensors in that it increases resistance when it gets heated. This unusual behavior makes it perfect for use as a self-resetting fuse or a motor protection sensor.

How PTC thermistors function

Switching vs smooth behavior

Some PTC devices display a steady increase in resistance as the temperature rises. Some, like protective kinds, have a sharp "switch" that happens at a certain temperature. Resistance rises sharply at this point, which sets off safety circuits. Designers need to make sure that the switching temperature is within the limitations of real-world use.

Main applications in 2025

Protection the Motor

Embedded PTC thermistors keep an eye on the temperature of the windings in current EVs and industrial drives. When the heat gets too high, the resistance goes up and the circuit shuts down. Focusens makes strong PTC sensors for this job.

Inrush/overcurrent limiting

A pts temperature sensor can also limit current. When the device is first turned on, it stays low, but as the temperature rises, it increases resistance and limits current. This makes it easier on big fuses and relays.

Self-regulating heaters & EV systems

Because PTC elements heat up and then stabilize, they serve as self-regulating heating elements. In EV cabins or battery thermal management systems, a PTC can replace more complex heater circuits. Focusens offers custom PTC modules built for OEM integration.

How to choose a PTC temperature sensor

Spec ranges & mounting tips

To begin, you need to set the switching temperature. Most PTCs work between 60 and 180 °C. Then examine the mounting: direct contact, adhesive, or embedded probe. Each of these changes the reaction time and accuracy. Use the values from the datasheet, but test them in your real application.

Response time & sizing

Thermal mass is important. A big sensor or a loose mount takes longer to respond. Smaller bead and good connection provide a faster response. Think about steady-state dissipation: can the sensor survive if it experiences a high temperature for a long time? Focusens tests their PTC sensors in the worst possible situations.

Testing & quality standards

Customers want things to be reliable. Request data on thermal cycling, drift, insulation resistance, and conformity with automotive regulations. At Focusens, we help OEMs with the APQP process and give them batch traceability.

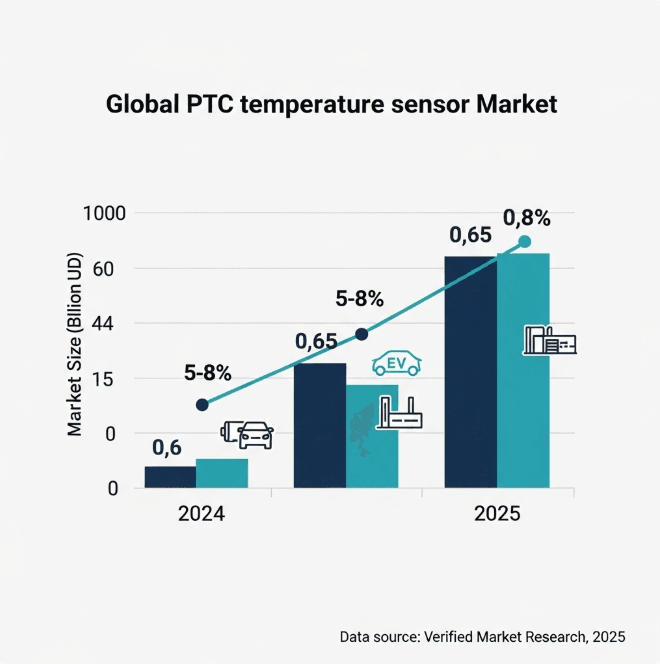

Market snapshot (2024-2025)

The global PTC thermistor market was estimated at approximately US$ 600 million in 2024 and is forecast to grow steadily over the coming years with a 5-8% CAGR. :contentReference[oaicite:0]{index=0} In parallel, the combined NTC & PTC thermistor market is forecast to exceed US$ 1 billion by 2025. :contentReference[oaicite:1]{index=1} This growth is driven by rising use of thermal sensors in EVs, industrial automation, and home-appliance systems.

Buyer checklist

- Switch-point temperature: defined point where resistance jumps.

- Mounting method: bead? probe? Embedded? Each affects performance.

- Thermal mass & response time: faster for safety-critical use.

- Test data: thermal drift, insulation resistance, aging.

- Supplier capability: Look for APQP, automotive-grade processes, custom options like Focusens offers.

FAQ

Q: What is a ptc temperature sensor used for?

A: A ptc temperature sensor (PTC thermistor) detects overheating and triggers protection, limits inrush current or acts as a self-regulating heater in automotive or industrial systems.

Q: How does Focusens support customization of PTC sensors?

A: Focusens offers custom PTC sensor design: choice of switching temperature, encapsulation, lead-wire length, mounting style, and batch testing for automotive markets.

Q: Why are PTC thermistors critical for motor protection?

A: In motors, an embedded PTC sensor can detect rising winding temperature and initiate shutdown before damage occurs—thus acting as a key safety component.

Conclusion & Next Steps

Selecting the right ptc temperature sensor means balancing switching behavior, mounting, size, and supplier reliability. At Focusens, we combine expert design, production capability and quality assurance to deliver sensors that meet automotive, industrial and heating-system demands.

+86-551-69109668

+86-551-69109668